As homeowners or HVAC professionals, ensuring the longevity and efficiency of air conditioning units is a top priority. A key challenge in this regard is AC coil corrosion. This blog by Bethel Products LLC will delve into the intricacies of AC coil corrosion, its causes, and robust strategies for AC coil corrosion prevention. From regular maintenance to selecting the right materials, we’ll guide you through the essential steps to protect your AC unit.

Understanding AC Coil Corrosion

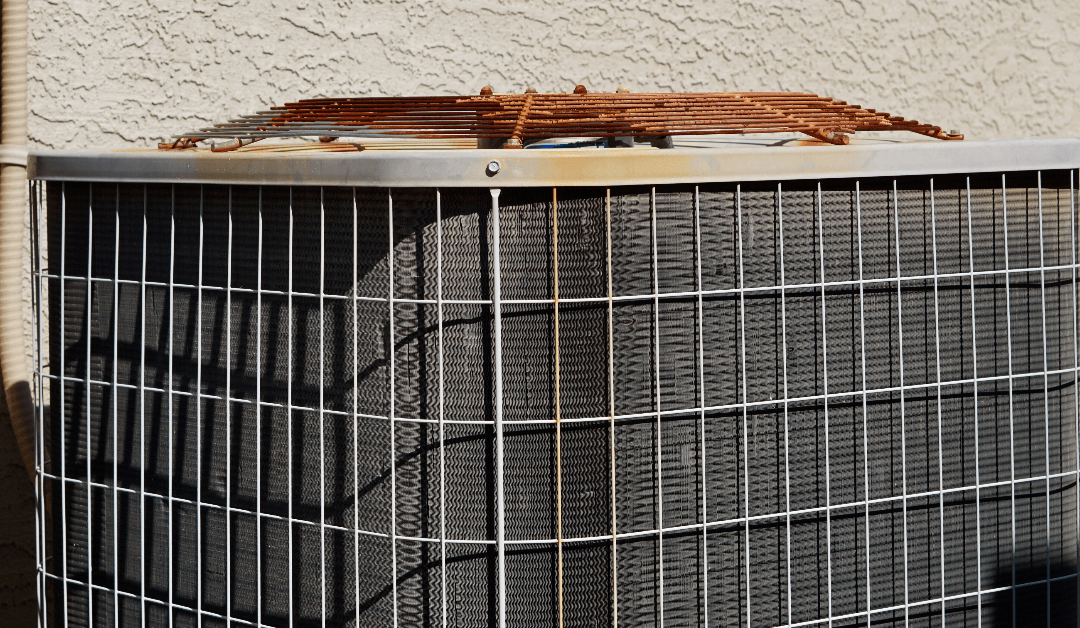

AC coil corrosion refers to the deterioration of the coils in your air conditioning unit, primarily caused by reactions with environmental elements. This corrosion can lead to reduced efficiency, higher energy costs, and even the complete failure of your AC unit. Understanding the phenomenon is the first step in effective AC coil corrosion prevention.

Common Causes of Coil Corrosion

AC coil corrosion is a gradual process influenced by several factors. Understanding these causes is key to effective prevention:

- Moisture: Excessive moisture in the air can lead to oxidation and rust formation on metal coils.

- Airborne Contaminants: Dust, dirt, and pollutants can accumulate on coils, creating a corrosive environment.

- Chemical Exposure: Exposure to harsh chemicals, such as cleaning agents, can accelerate corrosion.

- Lack of Maintenance: Neglecting routine maintenance allows corrosion to take hold.

- Salt Air: Coastal areas are particularly susceptible to accelerated coil corrosion due to salt-laden air.

Regular Maintenance and Inspection

Effective AC coil corrosion prevention starts with diligent maintenance and inspection. This vital process involves routinely checking and cleaning the AC unit’s coils. Over time, dirt, debris, and other environmental pollutants can accumulate on these coils, significantly increasing the risk of corrosion. By regularly cleaning the coils and following AC maintenance tips, you remove these potentially corrosive substances, thereby safeguarding the coils against deterioration. Furthermore, a thorough inspection allows for the early detection of any signs of corrosion, ensuring timely interventions. This proactive approach not only extends the lifespan of your AC unit but also maintains its efficiency and performance.

The Role of Protective Coatings

The application of protective coatings is a crucial step in AC coil corrosion prevention. These coatings serve as a defensive barrier, shielding the coils from various corrosive elements such as moisture, salt, and chemicals. By forming this protective layer, the coatings significantly reduce the direct contact of corrosive agents with the coil’s surface, thereby prolonging the coil’s lifespan. The right type of coating, selected based on the specific environmental conditions and the type of coils used, can effectively prevent the onset of corrosion and maintain the AC unit’s efficiency over a longer period. This preventative measure is a wise investment, as it can save considerable costs and effort in long-term AC maintenance and repair.

Choosing the Right Materials for AC Coils

Selecting the right materials for AC coils is a critical aspect of HVAC corrosion control. Copper coils offer robust corrosion resistance, making them an ideal choice for regions with high humidity or salt-laden air, such as coastal areas. On the other hand, aluminum coils are cost-effective but require proper maintenance and protective coatings to enhance their resistance to corrosion. Consulting with HVAC experts is advisable to determine the most suitable material for your specific environmental conditions, ensuring your AC system’s longevity and optimal performance.

DIY Tips for Corrosion Prevention

For the DIY enthusiasts, there are several steps you can take to protect your AC unit:

- Regularly clean and inspect your coils

- Use commercially available protective coatings for AC

- Ensure proper drainage and airflow around the unit

These simple yet effective measures can make a big difference.

Professional Solutions for Corrosion Control

When it comes to combating AC coil corrosion, professional solutions often provide the most comprehensive and effective approach. HVAC experts bring advanced techniques and specialized equipment to the table, crucial for thorough HVAC corrosion control. They can apply high-grade protective coatings, install corrosion-resistant components, and design maintenance schedules tailored to specific environmental conditions and system requirements. This professional expertise not only ensures a more effective corrosion control strategy but also provides the assurance of optimal, long-lasting AC unit performance.

Ensuring the Longevity of Your AC Unit

AC coil corrosion prevention is a vital aspect of maintaining your air conditioning system’s efficiency and longevity. By understanding the causes, implementing regular maintenance, choosing the right materials, and considering both DIY and professional solutions, you can significantly extend the life of your AC unit.

If you’re looking for expert advice or professional-grade corrosion control solutions, consider reaching out to Bethel Products LLC. With our specialized knowledge and products, we can provide you with the tools and support needed to keep your AC running smoothly for years to come. Contact Bethel Products LLC today to ensure your air conditioning system remains a reliable comfort source in your home or business.